The aerospace business in India is without doubt one of the quickest rising sectors with an more and more sturdy home manufacturing base. To achieve additional aggressive benefit, the implementation of latest applied sciences comparable to additive manufacturing has been gaining significance within the latest previous. Whereas this methodology results in price discount of constructing low-volume elements, in addition to permits the business to problem the boundaries of effectivity by means of extraordinarily correct and sophisticated design executions, the standard challenges confronted by this new manufacturing processes also needs to be completely addressed. Excessive-precision metrology options usually are not solely a possibility to optimize the manufacturing course of but additionally supply priceless perception for materials sciences and make sure the high quality of the output.

Additive Manufacturing as an Alternative in Aerospace

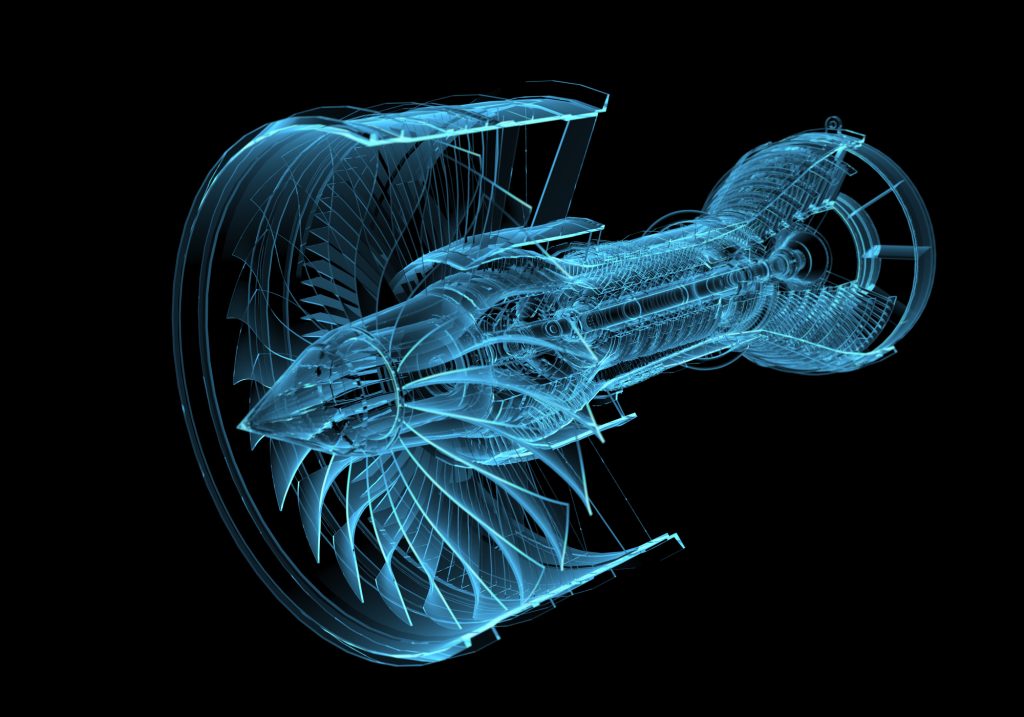

Air journey, a most popular mode of transportation, depends on plane elements assembly stringent high quality requirements. As an example, earlier than a provider commences manufacturing, as much as 1500 inspection options of a turbine blade have to be verified, adhering to tight tolerance ranges at each manufacturing step. Past this problem, one other is the very important upkeep and restore operations (MRO) which regularly entails changing high-complexity, quality-intensive low-volume or single elements. Conventional manufacturing processes for MROs show each time and cost-intensive, unable to satisfy the demanded complexity and accuracy effectively. Consequently, additive manufacturing, particularly 3D printing, is more and more built-in into the aerospace manufacturing chain in India, positioning the business as a pioneer in additive manufacturing innovation. Nevertheless, the adoption of this know-how brings its personal challenges, which our expertise suggests could be successfully addressed by means of high-quality metrology options.

Hitting the Brake: The Course of and Challenges of Additive Manufacturing

Powder is the constructing block of additively manufactured elements. The particles are small, sometimes starting from just a few micrometers to tens of microns in diameter. Their dimension distribution and form affect unfold capacity and therefore attainable defects would possibly happen in the course of the course of. The defect density is amongst different features and in addition an element for recycling and getting older of the powder. A uniformly distributed powder mattress is the important foundation for a steady and dependable additive manufacturing course of. Improper powder high quality, powder rheology and the method parameters would possibly trigger voids to kind within the closing construction. The additive manufacturing course of, in contrast to conventional manufacturing strategies, requires powders to be melted layer by layer in the course of the construct. Soften temperatures and course of parameters enormously have an effect on the crystallography and, as a consequence, half properties. After printing, the half remains to be hooked up to the construct plate. It’s then heat-treated for stress relieving and faraway from the construct plate with a band noticed or wire EDM. Some elements are then warmth handled once more for microstructure adjustments. These processes presumably affect the attribute and accuracy of the half, impacting the standard and security. Put up which, Dimensional accuracy and floor end are vital to make sure correct meeting and constant matching throughout a number of elements. Regardless that additive manufacturing is an immense alternative because it permits an unprecedented management over materials microstructures. Analyzing and understanding these constructions is essential for an environment friendly and optimized course of that ensures the demanded high quality and security.

Precision in any respect Altitudes: Overcoming the Challenges

Using cutting-edge measurement and inspection gear is essential for assembly aerospace elements’ refined necessities. Our metrology options help and could be applied all through the manufacturing course of, enabling rapid corrective actions, guaranteeing high-quality output, and selling sustainable resourcing. We make use of Mild or Electron Microscopes and CT for steady powder characterization, figuring out sources of high quality points within the powder mattress throughout or after printing. Faulty elements could be detected and glued in the course of the construct, avoiding downstream prices and growing yield. Optical 3D-scanners, Coordinate Measuring Machines, and high-resolution CT validate accuracy, examine completed elements, and analyze inside constructions, contributing to defining optimum settings for future processes. The excellent information evaluation throughout the method chain, facilitated by metrology gadgets outfitted with IoT and PiWeb software program by ZEISS, ensures correlation and helps an environment friendly and optimized course of. Investing in high-quality metrology and analysis gear is indispensable for guaranteeing security and high quality within the aerospace business, notably as ‘Make in India’ propels the sector’s progress, with additive manufacturing taking part in a significant function in materials science and course of optimization.

ZEISS, as a key world supplier, performs a pivotal function with its Blue Line course of, contributing to the business’s success by means of exact metrology and high quality options. Furthermore, the corporate’s dedication to excellence extends past mere provision, because it actively engages in collaborative ventures. The corporate’s globally distinctive utility lab not solely facilitates joint buyer tasks and scientific research but additionally serves as a dynamic hub for hands-on demonstrations. This collaborative strategy fosters a wealthy atmosphere for studying and information distribution, guaranteeing that the aerospace business advantages not solely from cutting-edge know-how but additionally from shared insights and collective experience.

In my view, the aerospace business in India stands on the forefront of innovation and technological developments, embracing additive manufacturing as a vital factor in its manufacturing chain. By leveraging cutting-edge measurement and inspection gear all through your complete manufacturing course of, the business can obtain rapid corrective actions, improve yield, and streamline useful resource utilization. With continued investments in high-quality metrology and analysis gear, the aerospace sector can guarantee the security and high quality of its intricate and sophisticated parts, additional solidifying its place as a pacesetter in technological innovation.

Supply Sr. Director- Aero & Rail

Cyient